RSS feed source: National Science Foundation

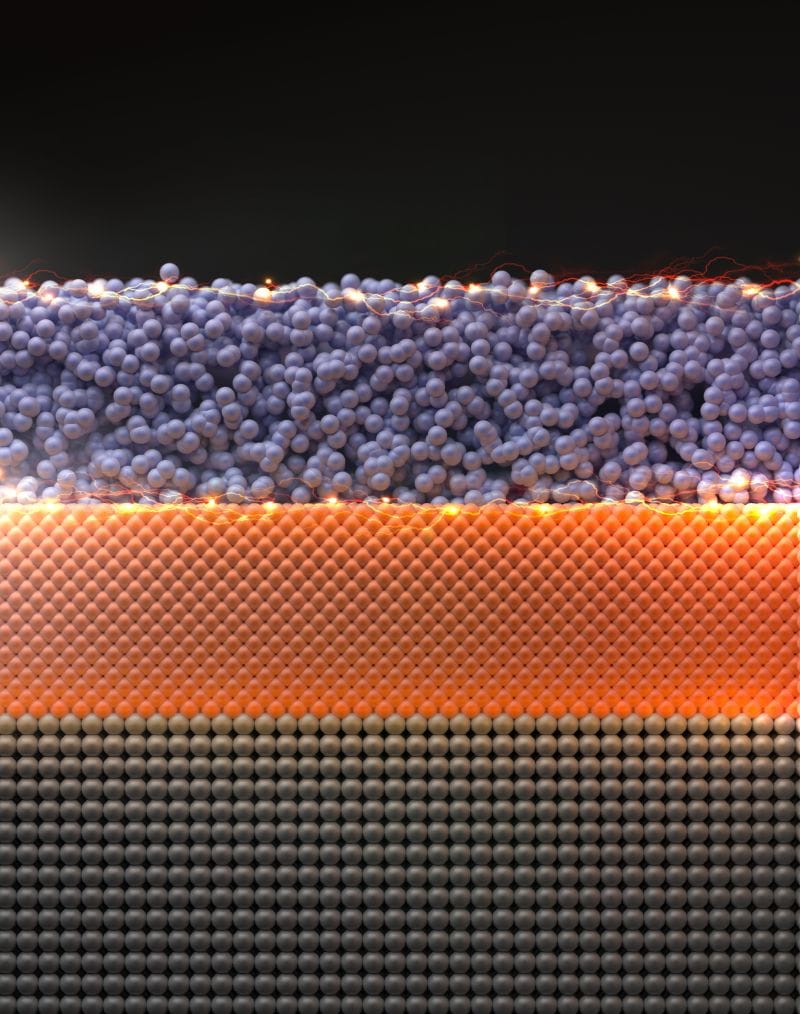

With multiple grants and research infrastructure provided by the U.S. National Science Foundation, researchers have shown that a newly developed material, niobium phosphide, can conduct electricity better than copper in films that are only a few atoms thick. These films can also be created and deposited at sufficiently low temperatures for compatibility with modern computer chip fabrication — and may help make future electronics more powerful and energy efficient.

So far, the best conductor candidates to outperform copper in nanoelectronics have had only exact crystalline structures, meaning they require very high temperatures to be formed. These new niobium phosphide films are the first examples of noncrystalline materials that become better conductors as they get thinner. The research is led by Standford University and results were published in Science.

“We are breaking a fundamental bottleneck of traditional materials like copper,” says Asir Intisar Khan, a postdoctoral researcher at Stanford University and an author on the research paper. “Our niobium phosphide conductors show that it’s possible to send faster, more efficient signals through ultrathin wires. This could improve the energy efficiency of future chips, and even small gains add up when many chips are used, such as in the massive data centers that store and process information today.”

RSS feed source: National Science Foundation

RSS feed source: National Science Foundation

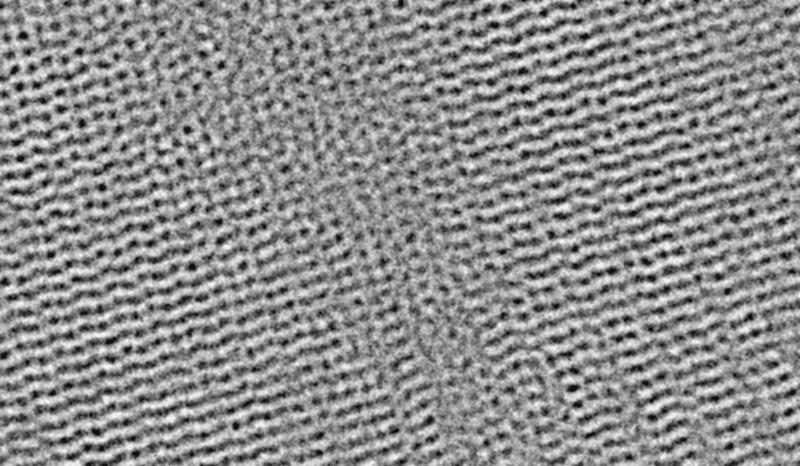

Researchers supported by grants and instrumentation provided by the U.S. National Science Foundation have created the first 2D polymer material that mechanically interlocks, much like chainmail, and used an advanced imaging technique to show its microscopic details. The material combines exceptional strength and flexibility and could be developed into high-performance and lightweight body armor that moves fluidly with the body as it protects it.

The nanoscale material was developed by researchers at Northwestern University and the electron microscopy was conducted at Cornell University. The results are published in a paper in Science.

RSS feed source: National Science Foundation

Supported by multiple grants from the U.S. National Science Foundation, researchers have comprehensively characterized the properties of a unique type of skeletal tissue with the potential for advancing tissue engineering and regenerative medicine. The tissue, called “lipocartilage,” is packed with fat-filled cells that provide stable internal support so the tissue remains soft and springy like bubbled packaging material.

The fat-filled cells in lipocartilage are called “lipochondrocytes,” which were first recognized in 1854 by Franz Leydig. The tissue is unlike most other types of cartilage, which rely on an external cellular matrix for strength. Led by the University of California, Irvine, the research team showed how lipocartilage cells create and maintain their own lipid reservoirs, remaining constant in size. Unlike other fat cells, lipochondrocytes never shrink or expand in response to food availability. The study was published in Science.

“Lipocartilage’s resilience and stability provide a compliant, elastic quality that’s perfect for flexible body parts such as earlobes or the tip of the nose, opening exciting possibilities in regenerative medicine and tissue engineering, particularly for facial defects or injuries,” says Maksim Plikus, a UC Irvine professor and author on the paper.

“Currently, cartilage reconstruction often requires harvesting tissue from the patient’s rib — a painful and invasive procedure. In the future, patient-specific lipochondrocytes could be derived from stem cells, purified and used to manufacture living cartilage tailored to

Click this link to continue reading the article on the source website.