RSS feed source: National Science Foundation

Artificial intelligence has transformed fields like medicine and finance, but it hasn’t gained much traction in manufacturing. Factories present a different challenge for AI: They are structured, fast-paced environments that rely on precision and critical timing. Success requires more than powerful algorithms; it demands deep, real-time understanding of complex systems, equipment and workflow. A new AI model designed specifically for manufacturing, seeks to address this challenge and revolutionize how factories operate.

With support from the U.S. National Science Foundation, a team led by California State University Northridge’s Autonomy Research Center for STEAHM has developed MaVila — short for Manufacturing, Vision and Language — an intelligent assistant that combines image analysis and natural language processing to help manufacturers detect problems, suggest improvements and communicate with machines in real time. Their goal is to create smarter, more adaptive manufacturing systems that can better support one of the most important sectors of the U.S. economy.

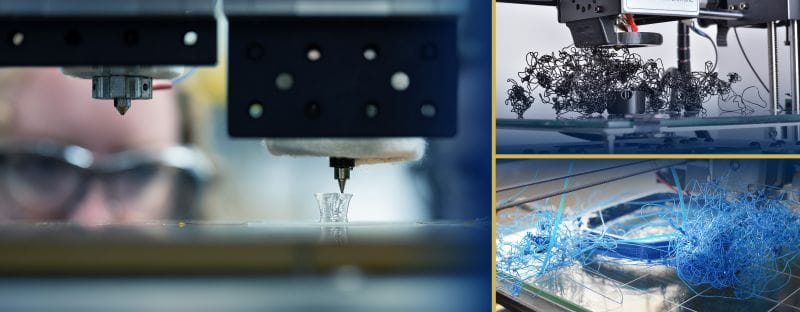

MaVila takes a different approach. Instead of relying on outside data, like information on the internet, it is trained with manufacturing-specific knowledge from the start. It learns directly from visual and language-based data in factory settings. The tool can “see” and “talk” — analyzing images of parts, describing defects in plain language, suggesting fixes and even communicating with machines to carry out automatic adjustments.

MaVila was trained using a specialized approach that required

Click this link to continue reading the article on the source website.