Link to the full source article

RSS feed source: National Science Foundation

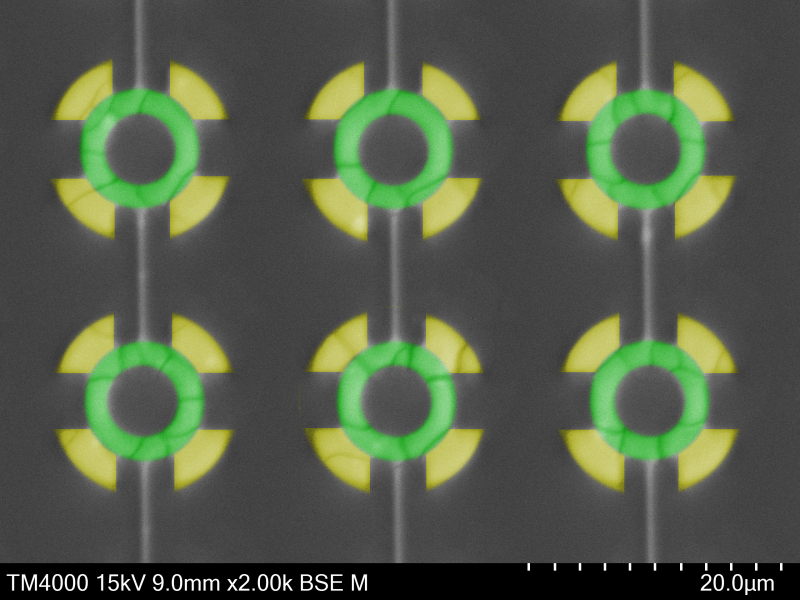

A new technique for creating simple electronic device components proved effective in recent tests. The results show that self-assembly for more complicated electronics, like 3D computer chips, could be possible.

The findings are published in Materials Horizons and supported by the U.S. National Science Foundation Center for Complex Particle Systems. The technique exhibits a relatively “passive” creation process compared to current industry methods, eliminating the need for high-cost robotic or manual labor.

The method explores arrays of transistors and diodes for now but could be used to fabricate more complex structures, such as 3D chips, in the future.

Martin Thuo is a professor of materials science and engineering at North Carolina State University and an author of the study. Says Thuo, “Existing chip manufacturing techniques involve many steps and rely on extremely complex technologies, making the process costly and time-consuming. Our self-assembling approach is significantly faster and less expensive.”